I've recently completed the 3D printed watch with tourbillon, designed by Christoph Laimer and published on Thingiverse in 2016. Here it is in operation:

You might notice that it does not remotely keep time: a minute on the watch is only about 43 seconds in real time. I'll say more about that later. A few more pictures:

In brief, the watch works like this. There is a mainspring in the base, which drives the minute train. The minute train is linked to the tourbillon, which locks and unlocks it and so provides the timing. The minute train drives the bronze (greenish) ring gear. Another gear takes the movement from this ring gear into the hour train, which ends up driving the gold ring gear.

I got my first 3D printer in mid-2015, and when this design came out in January 2016 I decided to give it a go. It completely failed to run, and I set it aside. This is not a surprising outcome. The printer was not very accurate, and I had no idea how to debug clocks and watches or even really much understanding of how they work. Time has passed, and now I have a Prusa MK4. It much more precise than my first printer, and also a lot faster. A consequence of the speed is that I am willing to print at much finer layer heights than before. On my first printer, I was probably using 0.3mm for large parts and 0.2mm for smaller ones. With the MK4, I nearly always use 0.15mm without worrying about how long the prints will take.

On the debugging side, I now have a better understanding of how clocks and watches work, and this helps in building up the mechanism in stages and do partial tests. The tourbillon itself is a self contained unit and I first tested it in isolation. Then I checked that the minutes train worked smoothly, separate from the tourbillon, then the minutes and hours trains together, and finally the whole mechanism.

Most of the parts are from the original design. The tourbillon spring is the medium strength one from A flight of hairsprings. I used the Massey pin in the balance wheel mechanism. It makes the balance wheel less prone to jam against the fork. The bridge on the top is modified from the logo-less version from the torque modification of the design. I decided not to use the hands from the original design as they don't attach very well, and instead printed the black notch you can see above directly into the ring gears.

Now to why the timing is off. When I first put the tourbillon together, I found that it would seize. The reason for this is that the balance wheel was swinging a long way on each tick. While it was at the ends of its movement, the fork could flop around. When the balance wheel swung back, the fork might not be in the right place for the balance pin to engage with it and everything locked up. Using a stiffer spring limits how far the balance wheel swings and so avoids this problem. However, it means the timing is no longer right. For a real timepiece, this would be an issue. But in my case, I intended it more as an objet d'art: something to look at. It isn't really a practical clock, as you can't tune the timing or even set the hands. If it ticks at the wrong rate, that's OK.

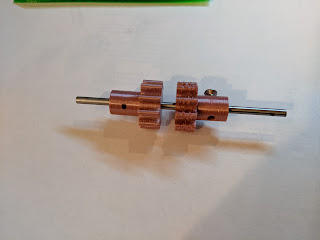

I modified a few of the parts. Many interior holes were too small. For the ratchet and ratchet bushing (check the thingiverse page if you want to know which parts these are), I slightly opened them up by editing the STLs in blender. For all of the gears in the minutes and hours trains, I could have drilled out the holes. Instead, what I decided to do was to modify them as follows. All of these gears run on 2mm arbors, so I made the axis hole slightly larger than this for the 2mm or so at each face of the gear (in Blender, again). The rest of the axis hole I made 2.4mm diameter. This means that when I drilled out the holes, I only needed to cut through the 2mm part at each end, so there is not much chance of the drill going askew. The rest of the interior of the axis hole does not touch the arbor, thus reducing friction. Steve Peterson uses this in his clocks, and I've mentioned it in a previous post.

The teeth on most of the gears are tiny, only about 1.5mm from tip to base. You need accurate printing followed by a close visual examination for any blobs or wisps of filament for them to work smoothly.

The filaments are Flashforge burnt titanium PLA for the body, gold and bronze silk PLA for the gears and moving parts, and PETG for the main spring. The burnt titanium filament looks very nice, but is not so good to work with. You get a lot of stringing and blobs, and the printed surfaces are slightly rough. The ring gears have a large contact area, so you really need something smooth and with low friction. Silk PLA is ideal for this.

The design also calls for a rather bizarre range of small screw sizes. I think many of these could be replaced with more standard sizes (or at least to use one or two sizes throughout) with minor design changes. I didn't try this, though it's noteworthy that the design included the original CAD model in Fusion 360 format, making such modifications easier.

How long will it run? From a full winding, I can get 20-25 minutes. I expect this will decrease over time as the mainspring weakens. Here is a 10x timelapse starting with a fully wound spring and letting it go until it stopped. With a nudge it will run for another minute or two.

And also a look at the mechanism in slow motion:

This is a remarkable design by M. Laimer (aka TheGoofy). It was one of the first 3D printed timepiece designs and it outclasses many more recent designs in the care and thought that went into it as well as the attention to its visual appearance. I would definitely rate it higher than, for example, the Tourbillon Mechanica, which just looks messy to me, or the many published tourbillon design which just don't run well. Very nice.